Table of Contents

How To Produce Double Wall Stainless Steel Insulated Water Bottle?

What is a stainless steel insulated water bottle ?

The stainless steel insulated water bottle is a container for water. It is made of SUS304 stainless steel, which can maintain the water temperature in the container without significant change for a certain period of time. In a broad sense, in addition to drinking water, insulated water bottle can also hold any other food and beverages. For example: milk, coffee, juice, rice, porridge, vegetables, etc. Because of its excellent thermal insulation performance, stainless steel insulated water bottle are widely used in outdoor activities and mountaineering tourism in addition to home life and office environments.

What is a stainless steel insulated water bottle ?

1.Raw material inspection of insulated water bottle

Before starting the production of insulated water bottle, we will carefully check the required stainless steel materials according to the customer’s order requirements, including the diameter, thickness, and nickel content of stainless steel pipes. In addition, we will also test the material of the accessories of the thermos cup, including the BPA content and the firmness of the plastic accessories, so as to ensure the safety and environmental protection of product quality.

2.Metal appearance processing of insulated water bottle

Metalworking is the first step in the molding of stainless steel vacuum bottles. The stainless steel pipe is expanded into a predetermined shape in the mold through the pressure of water. Or use the stretching machine to punch the stainless steel disc out of the required shape and length of the inner tank of the thermos bottles many times. In this production link, we use CNC machine tools to ensure that the external dimensions of each thermos cup are consistent, so as to reduce the scrap rate of products

3.The bottom of insulated water bottle shell welding getter

Metalworking is the first step in the molding of stainless steel vacuum bottles. The stainless steel pipe is expanded into a predetermined shape in the mold through the pressure of water. Or use the stretching machine to punch the stainless steel disc out of the required shape and length of the inner tank of the thermos bottles many times. In this production link, we use CNC machine tools to ensure that the external dimensions of each thermos cup are consistent, so as to reduce the scrap rate of products

4.Copper plating on inner liner of insulated water bottle

Copper plating on the inner liner of the insulated water bottle can effectively improve the insulation performance of the thermos cup. Under the same conditions, it is more durable than the noncopper insulated cup. The principle is that the existence of copper-plated film effectively reflex the heat transfer in the insulated water bottle.

5.Welding of the inner tank and the outer shell of the insulated water bottle

Welding the stainless steel liner and the outer shell of the insulated water bottle is a very technical process. We use the argon arc welding process for welding. The magnitude of the current and the length of the welding time are directly related to the firmness of the connection between the shell and the inner tank. In order to make all insulated water bottles meet a unified standard, we have realized fully automated mechanical operation in this process.

6.Ultrasonic cleaning of stains

Ultrasonic cleaning can effectively remove stains ininsulated water bottle. Utilize the cavitation, acceleration and direct flow of ultrasonic waves in the liquid to directly and indirectly affect the liquid and dirt, so that the dirt layer is dispersed, emulsified and peeled off to achieve the purpose of cleaning. Effectively clean the residual oil and other stains in the insulated water bottle thoroughly

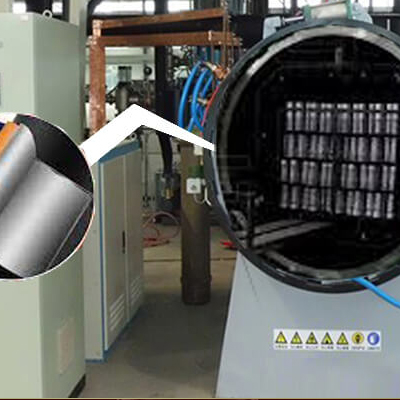

7.Vacuum treatment of insulated water bottle

As we know, the reason why the thermos water bottle can maintain the slow change of water temperature in the bottle for a long time is that there is a vacuum isolation layer between its shell and inner tank. There is no air between the inner tank and the shell of the thermos water bottle, so the water in the flask will not conduct heat and change the temperature. All this depends on the vacuum treatment process of the insulated water bottle, which is also the fundamental reason why our products sell well. Therefore, we have invested the most in quality control in this link to ensure the stability of product quality.

8.Insulated water bottle electrolysis

After the insulated water bottle is made and formed, the inner tank needs to be polished. Ordinary ultrasonic cleaning cannot solve this problem. So we chose to clean it electrolytically. Electrolysis is to improve the microscopic geometry of the stainless steel surface of the insulated water bottle and reduce its surface roughness through the combined action of the current of the positive and negative electrodes and the electrolyte, so as to achieve the purpose of bright and smooth metal surface of the insulated water bottle.

9.Insulated water bottle shell polishing

After the insulated water bottle is electrolyzed, the liner and outer shell will become smoother, but this is not enough. In order for the paint to adhere firmly to the outer wall of the insulated water bottle, it needs a better finish. Therefore, we will use the polishing process to grind the outer wall of the insulated water bottle, and use a higher mesh sand belt to carefully grind the outer surface of the insulated water bottle to achieve the preset target.

10.The outer surface of the insulated water bottle is painted

In addition to painting, the surface protection of the insulated water bottle can also be sprayed with plastic powder, the purpose of which is to protect the stainless steel material of the insulated water bottle from corrosion. Personalized color customization can also highlight its own brand cultural elements and highlight the unique design style of the insulated water bottle.

11.Logo making of the insulated water bottle

The insulated water bottle can be made with various types of logos, we can use screen printing, laser engraving, thermal transfer maps, uv printing and more ways to make logo. Personalized custom logos can also be used to customize the insulated water bottle as a promotional product and gift to others, further promoting your sales performance and enhancing your relationship with others.

12.Assembly and packaging of insulated water bottle

We usually complete the assembly of the insulated water bottle on the assembly line. Each different vacuum water flask has a different way of assembly, but all thermos water bottle products will be packaged in strict accordance with our strictest quality management system. According to the problems found in the packaging process, the managers of the packaging workshop will timely feedback to each production link to further improve the quality of the vacuum water flask.

13.Insulated water bottle quality sampling

After the insulated water bottle is assembled, we will arrange professional quality inspectors to conduct scientific sampling tests. Different insulated water bottle products will have great differences in the number of samples and detection methods. Generally speaking, we will focus on several aspects such as the performance of the vacuum water flask, the water leakage prevention and the smoothness of each part. To ensure that users get the best experience when using the insulated water bottle.

As a professional manufacturer of insulated water bottles, we have some different styles of the insulated water bottles, and most of them have a capacity of 500ml. Of course, we also provide insulated water bottles with different capacities for different customers to meet their different drinking water needs. If you need to customize insulated water bottles in batches, please contact our senior engineers, and we will provide you with a completely free solution as soon as possible